Thermal spray coating is often referred to as metal spraying. The thermal coating is a surface engineering/coating process that sprays metals, ceramics and polymers onto the surface of another material.

Alphatek offers a wide variety of coatings including HVOF (High-Velocity Oxygen Fuel), Plasma spray, Arc-wire, Flame spray, and Fluoropolymer.

The range of thermal spray coatings offered by Alphatek means that it’s possible to achieve a cost-effective and high performing finish that protects metal components from heat, wear, corrosion, fatigue and oxidation.

We have developed our thermal spray coating to meet customers’ specific application requirements, some are supplied to customers’ own specifications. All are applied and delivered to the highest quality and represent great value.

Our thermal coatings can repair damaged and worn components original specifications.

In this Alphatek blog, we are going to be discussing all things thermal spray coating and how you can get in touch with a specialist.

What Are The Types Of Thermal Spray Coating?

There are five main methods of thermal spraying, all of which project small molten or softened particles onto a surface to adhere and form a continuous coating. The temperature increase of the coated part is minimal, meaning heat distortion is rare – a major advantage over hot-dipped galvanising or welding.

Thermal spraying for corrosion control is usually carried out by Flame and Arc-wire – they are the least costly and quickest to implement, so are suitable for corrosion protection of larger structures. Plasma and HVOF sprays are used to apply engineering coatings and are of higher quality, density, and bond strength.

Let’s take a look at them individually

HVOF Spraying

HVOF (High-Velocity Oxygen Fuel) is a process to apply very dense, strongly adhered coatings.

HVOF uses the heat and pressure generated from the combustion of a liquid or gas fuel mixed with oxygen. The mixture is combusted in a chamber where it heats and expands, forcing the exhaust gases out of the gun barrel at supersonic speeds. As a result potential applications include: wear resistance, high or low friction, abrasion protection and many more.

Plasma Spraying

Plasma coating is the most versatile out of the 5 Alphatek can provide. It’s designed to treat industrial parts that are exposed to many different elements such as heat or wear and tear. When parts are passed through the spray coating process, they will become more durable, and their lifespan will be extended. However, the benefits of using this process include:

- Thermal Insulation

- Preventing Wear and Tear

- Protects from Corrosion

- Resistant to Oxidation

Arc-Wire Spraying

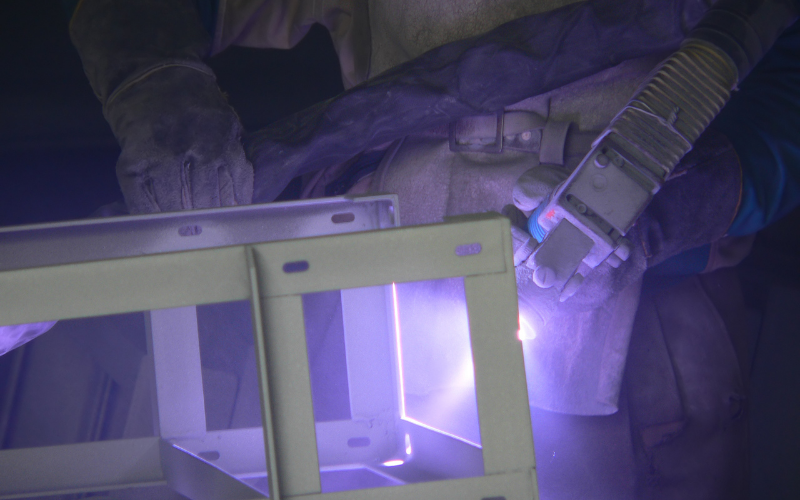

Arc-Wire spraying involves two consumable metal wires. When fed into the spray gun, these wires are electrically/thermally heated to their melting points and then sprayed onto a metallic surface.

This method of coating is especially suitable for providing corrosion protection to materials with low melting points such as aluminium and copper. Alloys whether Steel, Stainless Steel or non-ferrous combinations.

Flame Spray

Flame spraying is a thermal spray coating process that produces high-quality surface coatings using heat, from the combustion of a fuel gas with oxygen, to melt a spray coating material that is propelled onto a substrate.

Flame spraying is a cost-effective alternative for applying metallic and ceramic coatings in a low-velocity environment and for those delicate applications.

Fluoropolymer Coating

Fluoropolymer coating is a blend of high-performance resin and fluoropolymer lubricants. This specific coating offers many useful properties. They lend themselves and add real value to many individual applications. In short, Fluoropolymer Coatings are a design engineers’ dream, allowing greater flexibility of design from the start.

What Are The Benefits Of Thermal Spray Coating?

The main reason thermal spray coating is widely used is that the deposition rate of the surface is faster and easier than any other coating process. Let’s take a closer look at some of the benefits:

- Increased durability

- Modified electrical properties

- Increased or decreased corrosion protection

- Increased hardness

- Increased or decreased friction

- Increased wear resistance

- Additional protection to damaged materials

Many structures, equipment and vessels will not have to have their first maintenance of the coating before 20 years’ service, even in harsh environments, leading to significant maintenance cost reductions.

Alphatek: Get In Touch

There’s no real shortcut to experience. Here at Alphatek, we have a combined over 100 years of cumulative coating expertise in house. We have seen a lot.

Working closely with our customers over the years, we have developed our products and services to deliver the best value, most effective thermal spray coatings solution, first time, every time and with a stress-free service that suits everyone.

For Metal Spraying and Thermal Spray Coating specialists, look no further than us, Alphatek. You can call us directly on 01706 821021, or you can email us at postbox@alphatek.co.uk.

Alternatively, if you’d like to visit us we are located 20 miles north of Manchester. Just be wary of our opening times.